Gurley Lions Club serving the Gurley community since 1948

![]()

Gurley Lions Club serving the Gurley community since 1948

In January through March, 1892, The Gurley Record ran several articles about the manufacturing facilities existing in Gurley at the time. The most notable establishments were the Stave Factory, the Bucket Factory, and Eagle Pencil Mill. Following are quoted articles from the Record. This article is quoted from the March 30, 1872 issue and highlights the current Eagle Pencil Mill.

The Eagle Pencil Company of New York is the largest manufacturer of lead pencils in the

world and the pencil mill here belongs to that company and is a branch of the New York

business. It should be said that their mills here get out more cedar slats than any other

mill in the world. The plant here is under the management of its able and efficient

superintendent Mr. M. Hanover, who must be giving entire satisfaction to the company. The

business here seems to be conducted with perfect success.

There are many persons in our county who do not know that there is such an enterprise, and

few know of the magnitude of this manufacturing establishment. The mills here employ about

one hundred hands and pay out from three to five thousand dollars per month for operatives

and material. From three to four dollars per week are paid their female operatives and

their male operatives get from one to four dollars per day. They pay twice per month.

The material is purchased from the surrounding country for cash when delivered to the yard

at the mill. The yard covers several acres and the greater part of it is covered with

cedar logs, some of them being 25 to 30 feet high. Steam from a battery of steam boilers

drives the machinery of these mills.

The manner in which the work is done in these mills is very interesting indeed. The cedar logs are drawn up by means of a wire rope attached to a car which is moved by steam power up an inclined rail.

|

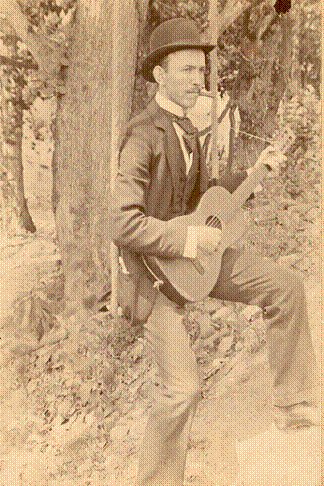

William A Walker Sr. worked for the Eagle Pencil Mill. |

The logs are cut by a large band saw into boards 2 1/2 inches thick. They are carried

to a cut off saw where they are cut into blocks the length of pencils. These blocks are

conveyed to the sawyers, of which there are quite a number. Here they are sawed into slats

2� inches wide and half the thickness of a pencil. From these saws, the slats fall down a

chute into a large room where 30 to 40 girls are engaged in assorting and packing them in

bundles for the dry house. The slats that unsuitable for pencils are carried to the boiler

house for fuel.

There are four dry houses connected with the mills which are solid brick. Both walls and

top of the brick were laid with the very best of mortar where the temperature is kept up

by steam pipes from 180 to 200 degrees, Fahrenheit. The slats are held until all the oil

is dried out of them, which generally requires about twenty or thirty days.

The slats are then carried to the packing house where they are crated for shipment to

the factory in New York. These mills cut 1800 gross of slats per day which out of which

are made the enormous number of 259,200 pencils.

As a large percentage of the cedar is not suitable for pencil making, it is apparent that

it requires a large quantity of logs to keep the mills moving ten hours for 7,200 feet.

The dust from all the saws in the building is carried through pipes by means of a blower

to the boiler room, where it is utilized as fuel to make steam power required to operate

the vast machinery of the plant. The entire building is warmed by steam making it

perfectly comfortable on the very coldest days of the winter.

Besides purchasing the cedar timber for pencils, they buy all the first class poplar logs

they can to saw into lumber for making crates in which to ship the cedar slats. For these

crates alone, 250,000 feet of lumber is required to ship a year's product from the mill.

So from this fact, something like an adequate idea can be formed of the great output of

the plant.

Mr. W. T. Roberts, a native of Alabama, is the bookkeeper and he possesses the confidence

of the entire community. Mr. Carl Lundenberg is the machinist that does the repairing of

the machinery. He is a very quiet and intelligent gentleman.

With the exception of the manager and machinist, all those hands connected with the mill

are people raised in the South, a fact that should be properly appreciated by our people.

The Eagle Pencil Company is financially one of the most substantial institutions in the

country. They are always liberal in their donations pt public enterprises. Unknown to the

general public, many a poor man has been paid for working on public roads when the donor

was unknown to him and the cash was furnished by the Eagle Pencil Company. Our people are

always willing to extend the right hand of fellowship to such enterprising gentlemen and

gladly welcome them to our town hoping they may be successful in their business beyond

their most sanguine expectations.

|

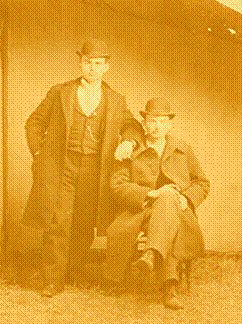

Unidentified friends of Will Walker and fellow workers - Gurley, AL, 1893 |

Note: These articles quoted by issues of the1892 Gurley Record were apparently written by young reporters who were inexperienced both in technical writing and a technical understanding of mechanical details. Their explanations are very simplistic and they seem to feel a need to heap a great deal of flattery and well wishes on the owners and principals of these businesses. Thus were the times...

Other news in this issue of the Gurley Record: